|

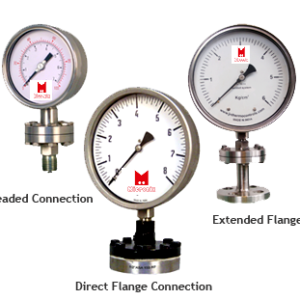

These gauges are used in corrosive environment and application, in the industries like Chemical, Processing, Petroleum Refining, Petro-Chemicals, Fertilizers, Pharmaceuticals & Bulk Drug, Food Processing and Offshore Application.

|

| Dial Size | 65mm, 80mm, 100mm and 150mm , 250 mm |

| Accuracy | ±1% F.S.D. (± 0.5% Optional), ±2% for 65mm dial. |

| Range | From -760MMHg (Vacuum)to up to +600 kg/cm2( All Std. Ranges) |

| Over range protection | 30% or as per class I / II of IS 3624. |

| Dial | Aluminium, Black graduation on white background. |

| Casing | Pressed SS304 Case and Snap action Bayonet Bezel, weatherproof as per IP65. |

| Mounting | Direct mounting bottom or backentry, Back entry panel mounting. |

| Connection | 3/8”, 1/2″ B.S.P. or N.P.T. , M 20 X 1.5 (M) and other |

| Bourdon & Socket | Stainless Steel 316L |

| Movement | Stainless Steel 304 |

| Fitments | Zero Adjustment Pointer and Blowout Safety Disc |

| Joints | Argon Arc welded. Heat treated stress relieved |

| Max. Temperature Limit | 270°C Max. |

| Optional Fitments | Toughened window glass, Electrical Magnetic NO/NC snap action contacts, Gauge Saver,Glycerine filling, Max. reading pointer etc. |