Application :

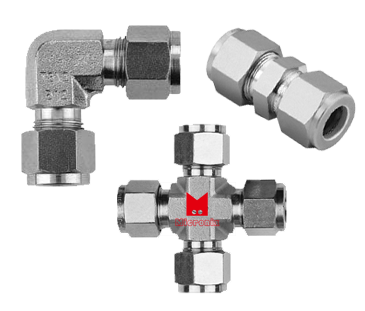

Hydraulic fittings are designed for use in Oil hydraulic, pneumatic systems, instrumentation systems in chemical plants, steel processing Industries, fertiliser, petrochemical and petroleum industries requiring high degree of precision and reliabililty. These fittings can be dismantled and reassembled for maintenance without loss of effectiveness of sealing.Fittings are available as standard for CD size metric tubing, Inch series fittings can also be manufactured.

Carbon steel fittings with Cadmium plating can be used in Corrosive application. For very aggressive applications use our Stainless steel fittings in A.|.S.l. 304 or A.l.S.l. 316, which are made in Single or double ferrule construction.

| Features: |

|

– Unique three piece design. – Ferrule takes seat on pipe surface when tightened, thus provides leak proof joint. – Case hardened ferrule for hard case and soft core for spring action and repeated use. – Light, Medium and Heavy pressure class. – Special Manganese based Phoaphatieing treatment of surfaces for corrosion resistance. – Cadmium plated ferrule for self lubrication. while assembly. – Special execution for Galvanised & Cadmium and Nickel plated finish. – Metric and Inch series fittings. – Strict quality check at each stage of manufacture. – Hydraulic test for compliance for each batch. |

| Technical data : |

| Tube Sizes: – 6 mm OD to 42 mm OD Pressure Ratings – 100 Bar for Light Series. – From 100 to upto 250 Bar for Medium Series. – From 500 to uptc 630 Bar for Heavy Series.Thread Sizes – From 1/8″ to 2″ B.S.P. / B.S.P.T. / N.P.T. – From M 8 X 1 TO M 48 X 2 in Metric thread Series. Thread Sealing – Tightening through packing collar. – Elastorheric Sealing. – O” Ring Sealing. – Tightening through Taper male threads. |

| Assembly Precautions : |

|

– Cut tubes at right angle without any Burr |